| MECHANICAL PROPERTIES | VALUE | UNIT |

| Tensile Strength, Max Load, XY | ASTM D638 | 48 MPa |

| Tensile Strength, Max Load, Z | ASTM D638 | 48 MPa |

| Tensile Modulus, XY | ASTM D638 | 1800 MPa |

| Tensile Modulus, Z | ASTM D638 | 1800 MPa |

| Elongation AT Break, XY | ASTM D638 | 20% |

| Elongation AT Break, Z | ASTM D638 | 15% |

| Flexural Srength (@5%), XY | ASTM D790 | 65 MPa |

| Flexural Srength (@5%), Z | ASTM D790 | 70 MPa |

| Flexural Modulus, XY | ASTM D790 | 1730 MPa |

| Flexural Modulus, Z | ASTM D790 | 1730 MPa |

| Izod Impact Notched (@3.2 mm, 23°C) | ASTM D256-A | 3.5 kJ/m2 |

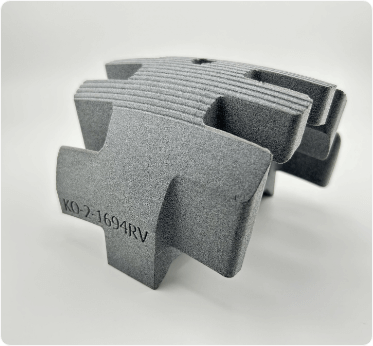

MJF Nylon PA12, used in Multi Jet Fusion 3D printing, is known for its high strength, precision, and durability. It offers excellent chemical resistance, reduced moisture absorption, and consistent coloring, making it ideal for complex, high-detail parts in automotive, aerospace, and consumer goods.