| MEASUREMENT | VALUE | UNIT | STANDARD |

| DENSITY | 0,95 | g/cm3 | N/A |

| TENSILE STRENGTH | 45 | MPa | DIN EN ISO 527 |

| TENSILE MODULUS | 1570 | MPa | DIN EN ISO 527 |

| FLEXURAL MODULUS | 1150 | MPa | ASTM D790 |

| IMPACT STRENGTH | 4,9 | kJ/m2 | DIN EN ISO 180 (Notched, Izod) |

| ELONGATION AT BREAK | 17 | % | DIN EN ISO 527 |

| HARDNESS | 75 | Shore D | ASTM D2240 |

| MELTING TEMPERATURE | 176 | °C | DIN EN ISO 1135 (20 °C/min) |

Actual values may vary with build conditions. Please note that values are measured after conditioning.

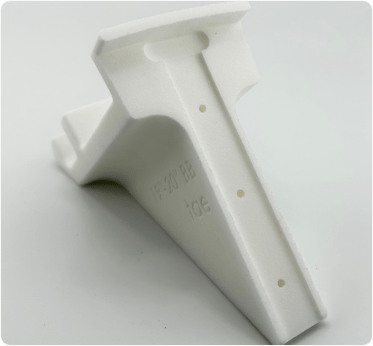

SLS nylon PA12, also known as Polyamide 12, is a synthetic thermoplastic polymer commonly used in Selective Laser Sintering (SLS) 3D printing. It's known for its exceptional strength, flexibility, and chemical resistance. Its low moisture absorption makes it ideal for functional parts and prototypes exposed to tough environments. SLS nylon PA12 is widely used in automotive, aerospace, and consumer goods industries due to its durability and fine-detail capabilities, making it a popular choice for complex geometries and moving parts in additive manufacturing.